Sweet Success: Bottom Loading Arm for a Leading Food Manufacturer

We were initially contacted by our customer to support their road tanker loading requirements at a new confectionery production site they were developing. The site was a blank canvas, as it represented a complete change of use from what had been there previously.

With the pipework being installed at the time, a site visit was scheduled within 48 hours to gain a deeper understanding of their setup and ensure no impact on any of the current or planned installation works.

Establishing the Requirements for the Loading Arm

The new site was intended to load various confections into road tankers, and the customer was keen to establish the safest and most efficient way of doing this. Many different solutions were discussed during the meeting, but it was agreed that bottom loading arms would be the best solution. It was established that the arms would need to meet the following requirements:

- Stainless steel construction

- Incorporate FDA approved seals

- Standpost with locking device

- Suitable for +80 degrees C

- Suitable for 15 Bar working pressure

- To include clean in place points on the arm to allow for cleaning / flushing

Separately, it was essential that they had the most efficient method of connecting to their tankers upon arrival to speed up the loading process.

Engineering the Bottom Loading Arm Solution That Ticked Every Box

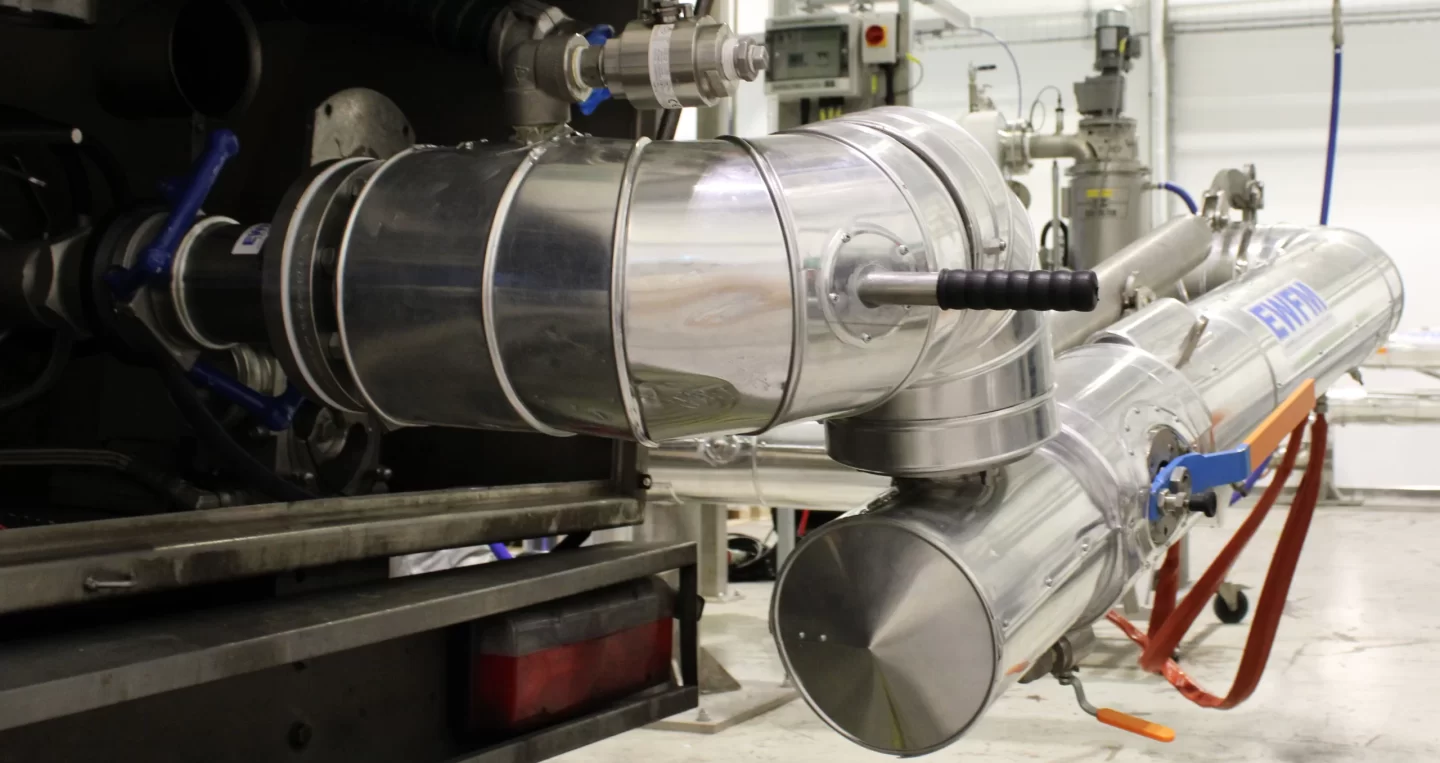

Working closely with the customer, it was agreed that our Model 2504 BC/JACK Bottom Loading Arm was the best solution for the project. The main reasons for this were:

- Triple range to ensure flexibility to reach tankers at different locations in their bays

- Hot water-heated to ensure the confectionery remains in perfect condition during loading

- Easy to manoeuvre into position and operate

- FDA approved

The MannTek Dry Disconnect Coupling was selected as the most suitable way to connect to their incoming tankers. Special EPDM seals, suitable for the product being handled, were also provided, with both the female side for the loading arm and the male side for the tankers included.

The arms were then designed and manufactured in collaboration with the customer to ensure that each one met the specific parameters regarding space and height at which they would be operating.

Since the successful delivery of the three arms, we have received positive feedback from the site. This has also led to further requirements for our loading arms for the next phase of their development, with two new arms currently being manufactured.

Do you also load and unload liquids or chemicals from road or rail tankers? It may be confectionery, it may be fuels, but if you have a similar need or enquiry, we invite you to contact us to explore how EWFM can provide a tailored solution for your requirement.

Visit the EWFM website for more information on Sweet Success: Bottom Loading Arm for a Leading Food Manufacturer